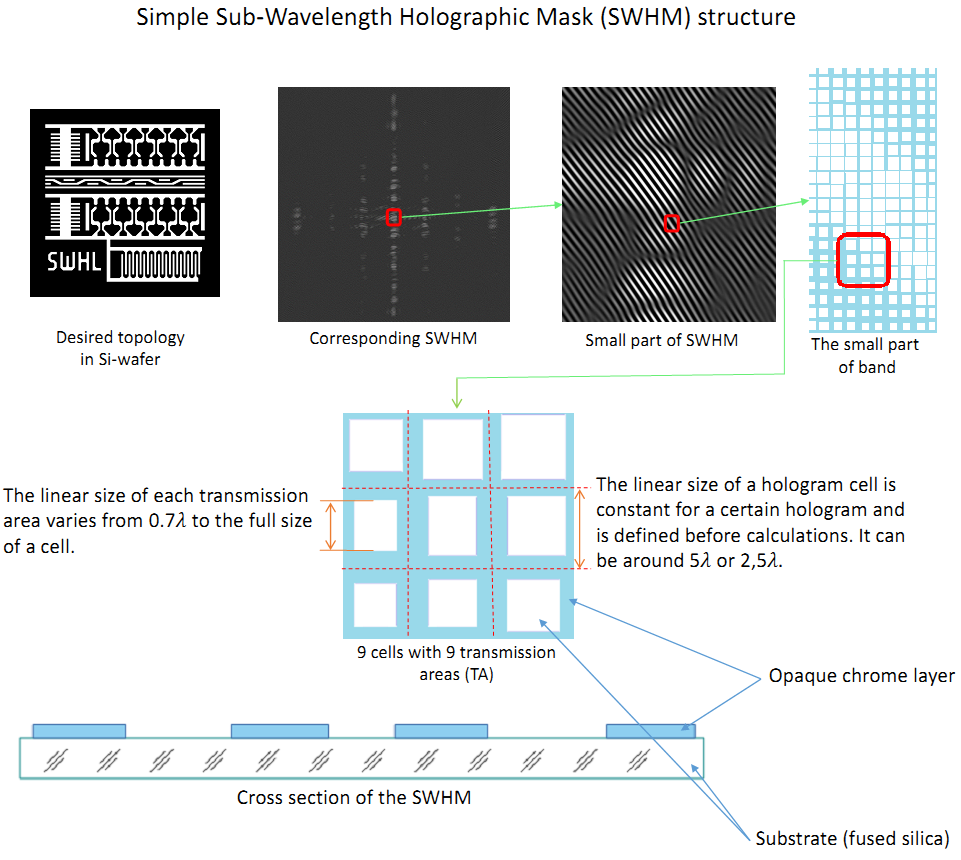

Holographic masks (SWHM) is manufactured by the common projection mask manufacturing technology; moreover, holographic masks are much simpler in producing and much less expensive because they consist of uniform elements (e.g. rectangles) of relatively large size. At a given light wavelength ("λ") a minimal element of the holographic mask will be more than 10 times larger than a minimal element of the projection mask. This is important since the size of the minimal mask element drastically affects the throughput of the mask generation equipment.

Holographic mask does not need regular control, maintenance and repair and has extremely long lifetime due to its low sensitivity to local defects and particles (by a factor of 109 – 1011 compared to common projection masks), that might appear during mask manufacturing and operation. For the same reasons holographic masks do not require special storing conditions, and the clear room requirements for lithography can be lowered significantly.

A holographic mask transmits less light than a projectional one. Nevertheless, SWHL does not have any projection optics, which stipulate considerable part of energy loss. On the whole, SWHL optical scheme efficiency is similar to projectional one.